When identifying hardware found on emergency exit and panic exit doors, it is extremely important to ensure suitable hardware is fitted in these applications, as an error may lead to hardware being installed that is not appropriate for the users concerned. This may result in tragic consequences in a fire or emergency.

In order to be sure that the correct hardware is fitted, there are 2 main standards that apply to emergency exit hardware and panic exit hardware. These standards are BS EN 179 (for Emergency exit hardware) and BS EN 1125 (for Panic exit hardware).

What is the difference between an Emergency Exit door and a Panic Exit door?

The terms ‘Emergency’ and ‘Panic’ have very different and very important meanings when used in relation to door hardware. Depending on which of these terms a particular door belongs to, will determine the performance requirements of the hardware which is fitted to it.

BS EN 179 covers hardware used on Emergency Exit Doors, so let’s take a look at the scope of that standard first;

BS EN 179 FOR EMERGENCY EXIT DOORS

This standard applies when a hardware device is to be fitted to a door where the users are familiar with the exit itself, and the hardware that is fitted to it. For example, trained staff in an office, who are aware of the escape route and who are previously trained on how to operate the escape doors and what to do in an emergency. Due to the familiarity all users are likely to have with the building and its escape procedures, it is deemed unlikely that a panic situation will develop and therefore the hardware can consist of items such as single push pad actuators, or lever handles, as long as the hardware conforms to BS EN 179. The hardware should allow safe and effective escape with one single operation to release the device.

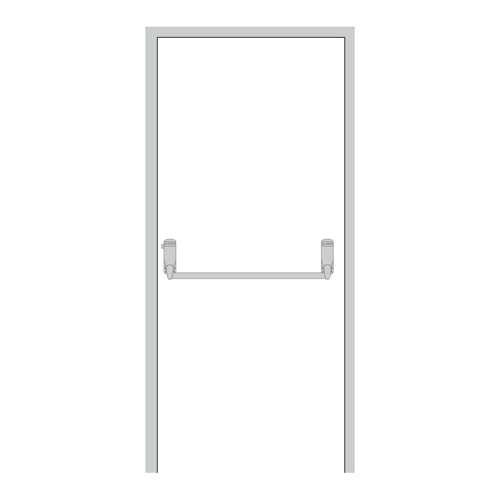

An example of an Briton 1438R Exit Device for single point locking to BS EN 179

BS EN 1125 however covers hardware used on Panic Exit Doors. Here is an overview of this standard;

BS EN 1125 FOR PANIC EXIT DOORS

This standard applies when a hardware device is to be fitted to a door where the users are not expected to be familiar with the exit itself or the hardware that is fitted to it. This may include public areas or areas likely to be occupied by people not trained in the building’s emergency procedures, such as in shops, restaurants, public buildings entertainment venues, etc. The Hardware fitted to these doors is required to perform its task without the user having any training or prior knowledge of how to use it. It should also require the minimum amount of effort to operate. These characteristics are what make it suitable for use in environments where a panic situation is likely to develop.

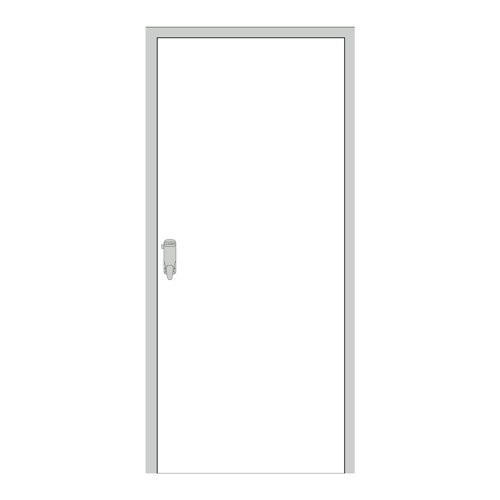

An example of a Briton 376 Panic Exit Device (BS EN 1125)

So, which do I need?

By understanding which of the 2 standards detailed above is most likely to be required of the hardware you are installing, consideration must be made to where the door is fitted, and who is likely to be using it. Where previous equipment is being replaced, and the existing hardware is still present, it can be checked to see which standard is satisfied previously. Ultimately however it is possible that previous hardware may have been inappropriate to begin with, and so it is always necessary to consider the building's use and occupancy.

All best practice guides recommend that where there is any doubt as to the building’s occupancy, devices conforming to BS EN 1125 should always be used as these will satisfy the minimum requirements of both standards. For an in-depth best practice guide on ascertaining the correct product for the application in question, the Door & Hardware Federation has compiled the following resource which gives clear information:

Where needed, an installer should seek to consult the relevant fire officer or person responsible for a building’s hardware specification prior to installation.

Classification of hardware

All hardware to either BN EN 179 or BS EN 1125 will be classified using a 10-digit code, which helps installers understand the limitations and suitability of a product for their needs.

The 10 digits refer to the product's performance in the following 10 areas: Category of use, Durability, Door Size/Mass, Fire Resistance, Safety, Corrosion Resistance, Security, Projection of Device, Type of Operation, and Field of Door Application.

Below is a breakdown of how each of these areas is measured as part of the classification:

Category of use

- Class 3 = high frequency of use by the public and others with little incentive to exercise care.

Durability (Cycle Testing)

- Grade 6 - 100,000 cycles

- Grade 7 - 200,000 cycles

Door size/mass

- Class 5 - doors up to 100kg

- Class 6 - doors up to 200kg.

- Class 7 - doors over 200kg.

Fire Resistance (EN 1634)

- Grade 0 - not approved for fire/smoke door use

- Grade A - approved for smoke door assemblies

- Grade B - approved for use on fire & smoke door assemblies

Safety

All door closers are required to satisfy the essential requirement of safety in use - only grade 1 is identified.

Corrosion Resistance (EN 1670)

- Grade 3 - high resistance

- Grade 4 - very high resistance.

Security

- EN 1125 - Grade 2 - up to 1000N.

- EN 179 - Grade 2 - 1000N

- - Grade 3 - 2000N

- - Grade 4 - 3000N

- - Grade 5 - 5000N

Projection of Device

- Class 1 - projection up to 150mm

- Class 2 - projection up to 100mm

Type of Operation

- EN 1125 Type A - ‘push bar’ operation

- Type B - ‘touch bar’ operation

- EN 179 Type A - ‘lever handle’ operation

- Type B - ‘push pad’ operation

Field of Door Application

- Category A - Single/Double door. Active or inactive leaf

- Category B - Single door only

- Category C - Double door only. Inactive leaf only

An Example classification on a BS EN 1125 product may therefore look as follows:

Hardware type; concealed / mortice or rim/surface fitting

Hardware for emergency doors can be either fitted to the surface of the door or can be morticed in or concealed within the door material, much like any other hardware. Aluminum doors are far more likely to feature concealed hardware.

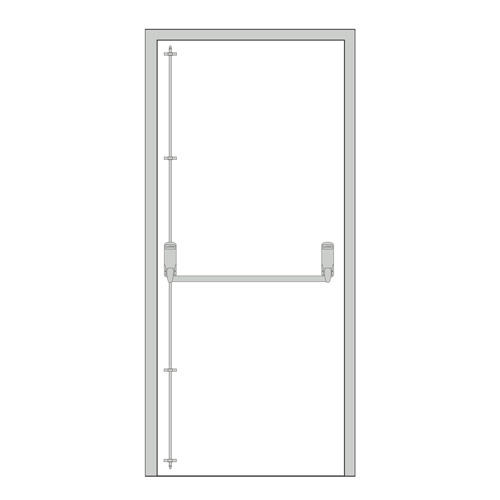

An example of a typical concealed hardware system for an aluminum door.

An example of a typical surface-fitted hardware system on a timber door.

Actuator types

Once the relevant standard has been established, the next logical consideration will be what type of hardware is required in relation to the part of the mechanism the user will interact with, for example, a bar across the door, a paddle handle, or a push pad, etc.

We refer to this part of the hardware as the actuator or activation device, and below are some common versions:

Paddle handles

Push Pads

Push Bars

Touch Bars

Number of locking points

The next thing to consider is the number of locking points that the hardware is required to have. The most common options are single-point, 2-point, and 3-point locking systems. Obviously, the security requirements and door type should be considered when identifying the number of locking points a system should have. A lightweight timber door in a low-security environment may only need a single locking point, whereas a heavy steel door to the rear of a high-security property would most likely benefit from a 3-point locking system.

Single-point locking

2-Point Locking system

3-Point Locking system

As in the images above, a single point locking system will usually have one locking point in the middle of the door, a 2 point will have 2 locking points with one at the top and one at the bottom, and finally, a 3-point system will have both a central locking point and a locking point at the top and bottom.

Locking point types

Once you know how many locking points are required, it's time to consider which type of locking point is needed. The common types of locking points found on escape hardware are as follows:

Sprung Latch

Pullman Latches

These can be either vertical or horizontal. Pullman latches differ from traditional latches as they are smoother and quieter in operation and are well suited to high traffic environments, they pivot inwards and return to a projected state that differs from that of a traditional latch meaning they have special keeps with a 45-degree recess. Pullman latches are often used on commercial doors and busy entrances.

Rods / shootbolts

One of the most common forms of locking device found on basic 2- and 3-point locking systems are vertical rods that locate directly into sockets or keeps on the frame, often simply referred to as shootbolts.

Here we see a top shootbolt and a bottom shootbolt on a standard 2-point panic hardware system.

Outside access devices

The hardware covered so far relates to use from the inside of the building, but it is also possible to operate the hardware from outside the building if required. The device used to achieve this is always referred to as an Outside Access Device.

These devices are essentially handles, either lever or ball knob type, which operate a follower in the back of the escape hardware to operate the locking points in the same way the actuator would normally. This can be useful if an escape door is also required to offer a means to enter the building, however, it should be noted that often these devices are very basic locking handles. What this means is that once unlocked, they remain unlocked until they are locked again. It is therefore important to remember that if you unlock an Outside Access Device and use it to enter a building, the device will remain unlocked and allow users to freely enter the building until it is locked again, which can only be done from the outside!

Here are some common outside access devices:

Knob variation

Lever variation

Digital lever and knob handle outside access devices

It is also possible to have a digital lock work as an outside access device. These are often desirable as contrary to the point stated above, a digital lock will re secure after use, meaning the entrance will not remain open to users as does not need to be relocked from the outside.

Common digital lock outside access devices include:

Lockey’s 2230NLS

Codelocks CL500PK (This can also be provided with a code-free function offering free passage when required by ordering the CL505PK variant)

Fixings

Finally, when considering which panic hardware to order for a specific application it is important to ensure the correct fixings are going to be included or purchased separately. Different door materials will require different fixings. A metal door for example will require hardware that is supplied with correct metal fixing screws etc. It is best to speak to our sales team if you are unsure on the required fixings for your project.

Finishes

Once you have identified the correct hardware select a finish option. Standard finishes are usually satin enamel silver, however black hardware is widely available and hardware specifically for UPVC such as Exidor’s 500 series will ordinarily be supplied in white. Some manufacturers also offer a range of brass and chrome finishes which are usually available via special orders. If you have any special requirements such as custom powder coating to RAL colour codes etc, this can usually be arranged via either the manufacturer or a 3rd party.

So, to summarise. When selecting panic hardware, consider:

- The standard to which the hardware is required to conform

- The classification of the hardware. Is it suitable for the application?

- Is the hardware concealed, or surface fixed?

- What activation device is needed?

- The number of locking points.

- The type of locking points needed.

- Whether an outside access device will be required

- The fixings for the door material

- The desired finish